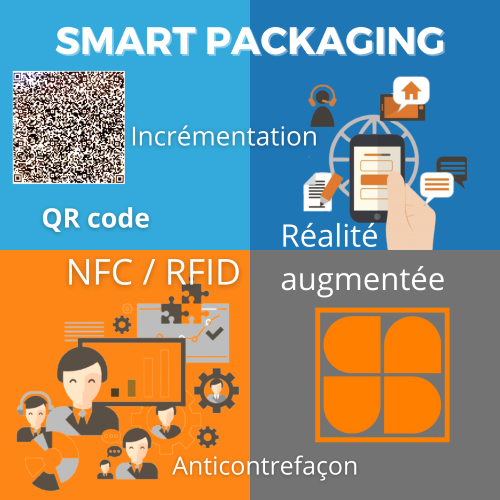

SMART PACKAGING

QR code, NFC, RFID, the technical possibilities for connecting products via their packaging or labelling are numerous today. Which solutions should you choose, for which type of application? We provide you with the first answers below to guide your project.

QR code, the “light” version

The QR code, in its version of identical reproduction, or with its variant with variable incrementation and encoding, can be considered as a gateway to the Internet of Things. Its possibilities (and limitations) are described below:

Large but limited number of characters (7,089 numeric, 4,296 alphanumeric), including a link to web pages (free or secure access)

Unique identifier based on an increment, and possible repetition of this code in printed characters.

Easily reproducible (without any notion of security), and easy to implement quickly (no mobile interface)

La réalité Augmentée (A.R)

Le packaging, et a fortiori l’étiquette est le support idéal pour l’intégration de la Réalité Augmentée :

- Intégration et modification possible à tout moment (supports spécifiques ou déjà imprimés)

Augmentation avec des contenus très riches : URL /Vidéo / Audio / Tél / Email / Vcard / Webview / Objet 3D

Récupération de précieuses datas directement sur le produit: parc mobile utilisé, volumétrie des scans / clics, dates et horaires, pages et interactions consultées, géolocalisation…

Tag NFC, l’échange direct avec le client

Le tag NFC (Near Field Communication) est constitué d’une puce, intégrée dans une capsule (étiquette ou manchon). Il utilise une norme unique et mondiale, compatible avec la plupart des smartphones. Il fonctionne uniquement en « champ proche » (fréquences HF-Haute Fréquence)

Ses applications les plus courantes sont donc :

- L’envoi de données appropriées et ciblées à un utilisateur ou un client, sur son smartphone (avis, accessoires,)

- La fidélisation client (réassort, localisation de point de vente ou de collecte)

- La traçabilité et l’authentification du produit, grâce à l’identifiant unique de chaque puce (avec différentes possibilités de clé de verrouillage)

Tag RFID, pour l’industrie et la logistique

Le tag RFID (Radio Frequency IDentification) est lui aussi constitué d’une puce, intégrée dans une capsule (étiquette ou manchon), à laquelle est associée une antenne ; Il utilise des fréquences UHF (Ultra Haute Fréquence), permettant une lecture à distance avec des équipements dédiés (type PDA).

Ses intérêts sont donc principalement pour l’industrie :

- Besoin minimum d’intervention humaine (lecture possible par « portiques », sans identification ou intervention d’un opérateur)

- Traçabilité des produits

- Gestion automatique des stocks, avec lecture de masse

Dans les deux cas de Tags (NFC, RFID), ceux-ci permettent à des interlocuteurs multiples d’accéder à de l’information et de la compléter, tout en n’ayant accès qu’aux informations autorisées.

Ces tags fonctionnent dans tous les cas avec un système d’interface. Il s’agit de plateformes mobiles et interfaces web permettant la communication entre les appareils de lectures et les systèmes d’enregistrement.

1 tag = plusieurs utilisateurs et niveaux de lecture

Les derniers développements sur ce marché :

- Tags pour contrôle de l’humidité, de la température, et des chocs

- Tags hybrides NFC/RFID

Décomatic maitrise l’intégration de tous ces éléments dans ses produits étiquettes et manchons, et s’appuie sur un partenaire pour proposer Tags et interfaces mobiles, et ERP.